SIRV

กระบวนการผลิต

- การฆ่าเชื้อ

- อาหาร | เครื่องดื่ม

- ยา | โภชนาเภสัช

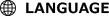

SIRV ออกแบบมาเฉพาะสำหรับวัตถุดิบแบบเม็ด โดยเน้นการออกแบบที่กะทัดรัด ราคาประหยัด และบำรุงรักษาง่าย มีจุดเด่นคือวาล์วหมุนแรงดันสูง วัสดุจะถูกปล่อยเข้ามาในวาล์วหมุนที่มีการป้อนไอน้ำแรงดันสูงเอามาอยู่แล้ว เพื่อให้วัตถุดิบและไอน้ำสัมผัสกันโดนตรงและทำการฆ่าเชื้อด้วยความร้อนจากไอน้ำนี้ โดยหลังจากกระบวนการฆ่าเชื้อเสร็จสิ้น ผลิตภัณฑ์ก็จะถูกส่งไปยัง ส่วนของการไล้ไอน้ำและความชื้นออกบางส่วนและผ่านไปยังส่วนทำความเย็นแบบสั่นสะเทือน และปล่อยสู่ระบบบรรจุคต่อไป

คุณสมบัติ

- การออกแบบระบบที่เรียบง่าย

ส่วนประกอบหลักคือวาล์วหมุนที่ออกแบบมาเป็นพิเศษ ซึ่งช่วยให้ระบบมีขนาดกะทัดรัด ประหยัด และดูแลรักษาง่าย - ประสิทธิภาพการฆ่าเชื้อที่ยอดเยี่ยม

ไอน้ำร้อนที่มีพลังงานความร้อนสูงจะถูกพ่นตรงเข้าไปในช่องของวาล์วหมุน เพื่อฆ่าเชื้อ E coli, เซลล์ที่มีชีวิต และเซลล์ทนความร้อน ในเวลาเพียงสามถึงสิบวินาที - การใช้งานที่ยืดหยุ่น

ความสามารถในการปรับเปลี่ยนแรงดัน อุณหภูมิ และเวลาในการทำความร้อนทำให้ระบบสามารถรองรับวัตถุดิบแบบเม็ดต่างๆ ได้อย่างยืดหยุ่น - ทำความสะอาดง่าย

ท่อลมสามารถทำความสะอาดได้ง่ายโดยการล้างน้ำจากตัวป้อนวัสดุ และทำให้แห้งด้วยเครื่องทำความร้อนในระบบ

การใช้งานทั่วไป

เครื่องเทศ / ธัญพืช / วัสดุเม็ดอื่นๆ

แผนผังกระบวนการ

ตัวอย่างข้อมูลการฆ่าเชื้อ

| วัสดุ | ก่อนการทำการฆ่าเชื้อ | เงื่อนไขการทำงาน | หลังการทำการฆ่าเชื้อ | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| จำนวนเซลล์ที่มีชีวิต (จำนวน/กรัม) | จำนวนเซลล์ทนความร้อน (จำนวน/กรัม) | E coli | ความชื้น (%) | แรงดัน (MPaG) | เวลา (วินาที) | จำนวนเซลล์ที่มีชีวิต (จำนวน/กรัม) | จำนวนเซลล์ทนความร้อน (จำนวน/กรัม) | E coli | ความชื้น (%) | |

| พริกไทยดำ | 1.6×107 | 4.8×105 | (+) | 10.8 | 0.55 | 5.5 | 8.0×102 | 6.0×102 | (-) | 11.0 |

| บัควีท (เปลือก) | 2.0×104 | 1.2×102 | (+) | 10.1 | 0.20 | 4.5 | < 300 | < 300 | (-) | 9.7 |

| งา | 1.2×104 | 8.0×103 | (+) | 4.7 | 0.20 | 4.5 | < 300 | < 300 | (-) | 4.7 |

* วิธีการวิเคราะห์: เซลล์ที่มีชีวิต: โดยใช้การเพาะเลี้ยงบนจานวุ้นมาตรฐาน เซลล์ทนความร้อน: โดยใช้การเพาะเลี้ยงบนจานวุ้นมาตรฐาน (ต้มนาน 10 นาที) E coli: โดยวิธี BGLB ความชื้น: โดยวิธีการทำให้แห้ง.

ข้อมูลลักษณะของเครื่อง

ขนาดและน้ำหนัก

| รุ่น | ขนาดตัวเครื่อง / น้ำหนัก | |||

|---|---|---|---|---|

| ความกว้าง (มม.) | ความยาว (มม.) | ความสูง (มม.) | น้ำหนัก (ตัน) | |

| SIRV-20 | 3,600 | 2,100 | 3,900 | 3 |

| SIRV-50 | 4,600 | 2,600 | 5,000 | 4 |

| SIRV-100 | 5,500 | 3,100 | 6,200 | 5 |

※ ต้องมีพื้นที่เพิ่มเติมสำหรับการใช้งานและการบำรุงรักษา

☆ มีโรงงานนำร่องที่พร้อมใช้งานที่สถานที่ของเรา

☆ สเปคเครื่องอาจมีการเปลี่ยนแปลงโดยไม่แจ้งให้ทราบล่วงหน้า

ความสามารถและการใช้พลังงาน

| รุ่น | ความสามารถ | การใช้พลังงาน | |||

|---|---|---|---|---|---|

| กำลังการผลิต (กก./ชม.) | แรงดันสูงสุด (MPaG) | เวลาการฆ่าเชื้อ (วินาที) | ไอน้ำ (กก./ชม.) | พลังงาน (กิโลวัตต์) | |

| SIRV-20 | 200 | 0.55 | 3 ถึง 12 | 80 | 30 |

| SIRV-50 | 500 | 0.55 | 3 ถึง 12 | 200 | 50 |

| SIRV-100 | 1,000 | 0.55 | 3 ถึง 12 | 350 | 65 |

※ ความจุสำหรับเม็ดที่มีความหนาแน่น 0.5 กก./ลิตร ขึ้นอยู่กับคุณสมบัติของวัสดุ

※ การใช้ไอน้ำขึ้นอยู่กับประเภทของวัสดุและสภาวะการทำงาน

※ การใช้ไอน้ำเป็นไปตามการทำงานปกติ ในการเริ่มต้นและการทำความสะอาด อาจต้องใช้ไอน้ำประมาณ 5 เท่าของปริมาณปกติ

※ ต้องการน้ำสำหรับการทำความสะอาด