Background

As people become more and more health-conscious, functional natural products are drawing attention.

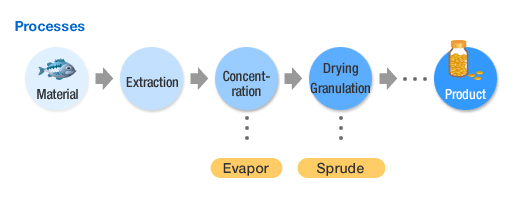

A seafood processor has started studying a new business to commercialize natural marine extracts as health foods with a new production line.

Problems

It is apparent through our research that the product has quite a new function. To commercialize it, however, we must overcome the following problems.

- This is a challenge to a new market. Though we know the function of the product, we have no idea about a machine which can produce an excellent end product, keeping the quality.

- We cannot produce a sample product for commercialization because we have no pilot plant.

- The commercial plant must be automated and run continuously.

![]()

Solutions

For their request to install facilities for concentration, drying and granulation, we will propose the Evapor to evaporate the extract without thermal deterioration and the Sprude to dry and granulate the concentrate with a single unit. To help them produce a sample product, we will introduce a contracted manufacturer.

Results

We accepted the proposal of Okawara and obtained the following results.

- We could purchase the facilities for concentration, drying and granulation from a single source for a short period.

- We could produce a sample product in time for commercialization of the product.

- The new production line was automated and ran continuously.