EVAPOR

- Evaporation / Liquid Concentration

- Food and Beverage

- Organic Chemicals

- Inorganic Chemicals

- Pharma and Nutraceutical

The spinning cone of the EVAPOR not only helps to prevent foam formation but also decreases the contact time between the product and the heating surface to less than one second at evaporation temperature as low as 35oC to further reduce the thermal impact and preserve maximum functionality of the product active compounds.

The centrifugal design also helps the EVAPOR to achieve higher concentration level than traditional evaporators.

Benefits

- Low-temperature evaporation and extremely short residence time result in an ideal equipment for heat-sensitive quality products

- Large overall heat transfer coefficient resulting in a high evaporation capacity per equipment

- Foaming is minimized by centrifugal force

- Able to produce concentrates with considerable higher soluble solids level and higher viscosity than traditional plate or tubular evaporators.

- Small product hold-up inside the equipment

- Evaporation surface can be monitored during operation.

- Hygienic design with easy evaporation surface cleanability. CIP available.

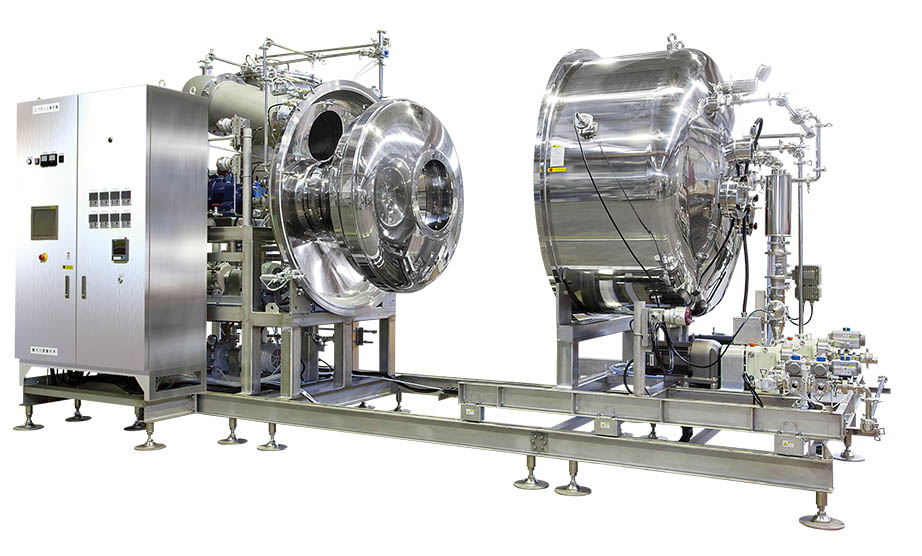

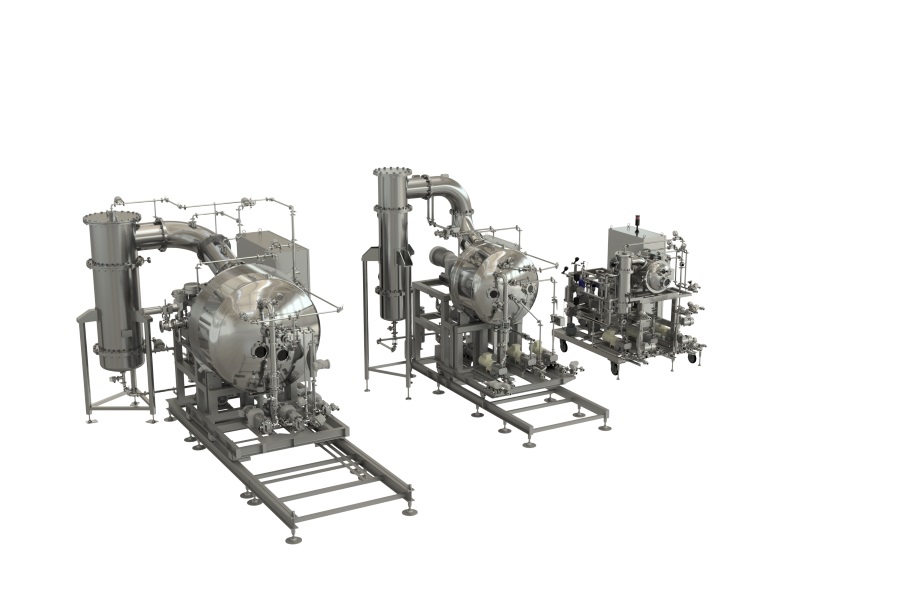

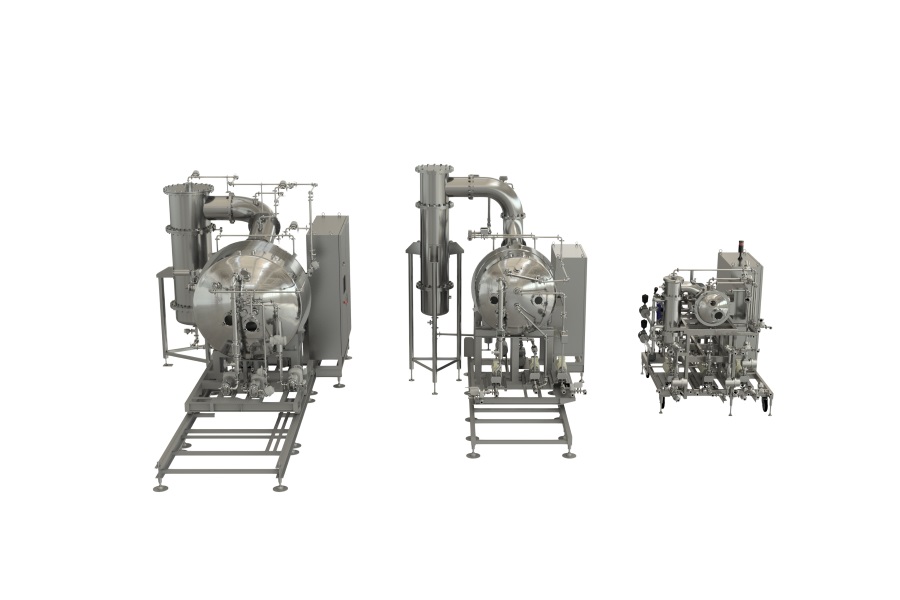

- Compact and practical design to facilitate installation

Typical Applications

- Penicillin and antibiotics

- Pharmaceutical Intermediates

- Herbal and botanical extracts

- Natural seasonings

- Extract (meat, fish, mushroom, etc.)

- Flavors

- Tea and Coffee

- Juices, fruit and vegetable extracts

- Vitamins and actives ingredients

- Synthetic resin

- Enzymes and proteins

Operating Principle

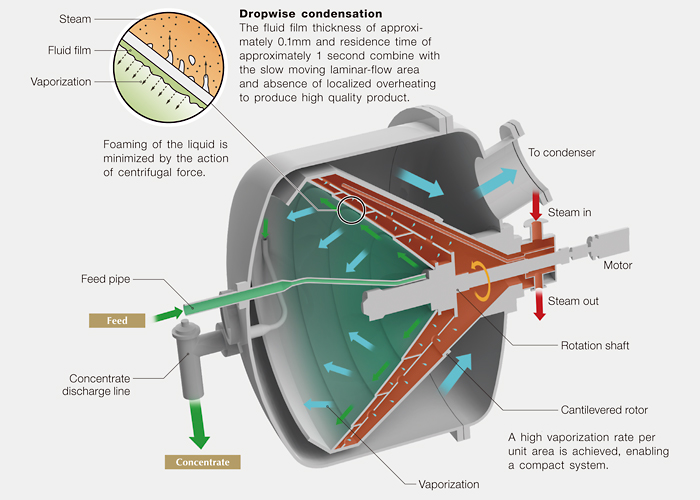

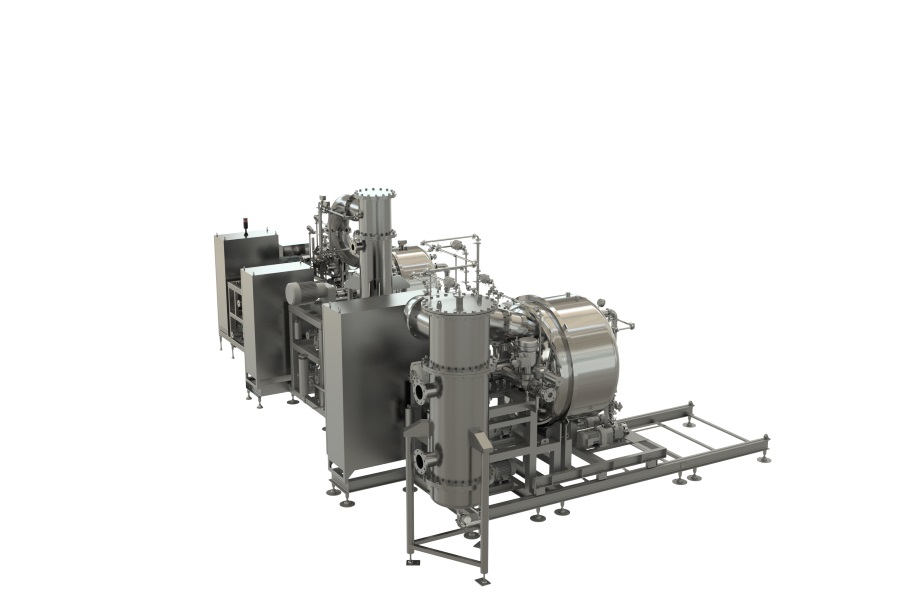

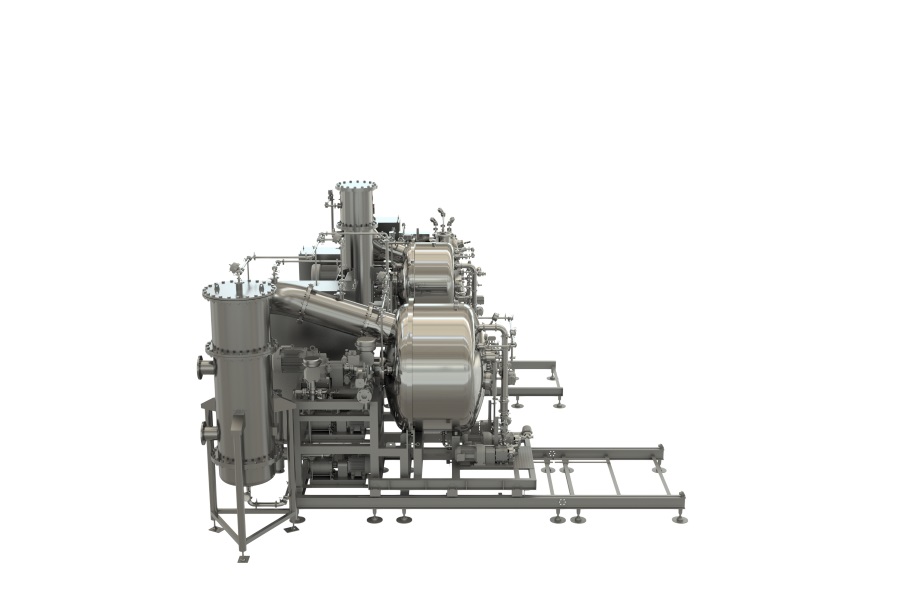

EVAPOR is a single effect, thin-film centrifugal evaporator that works under vacuum. The system consists of a hollow disc cone rotating on a horizontal cantilevered shaft and uses steam as heating medium.

The material to be concentrated is pumped into the equipment through a feed tube that delivers the liquid right in the bottom of the spinning cone. Centrifugal force created by rotational velocity of the spinning cone spreads the liquid out over the entire heating surface in a very thin liquid layer ( ≤ 0.1 mm), passing across the heating surface in a very short time – less than one second. The material is instantly heated to the boiling point temperature which is controlled by the operating pressure (vacuum) in the system. The concentrate material is then collected at the periphery of the spinning cone by a stationary paring tube and pumped out of the equipment while the product vapor will flow to a condenser where it will get condensate and then get discharged by a condensate pump.

Over 620 “EVAPOR” units have been delivered worldwide for a wide variety of applications in industries such as pharmaceutical, nutraceutical, fine chemical, biochemical, food & beverage, among others.

Video

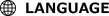

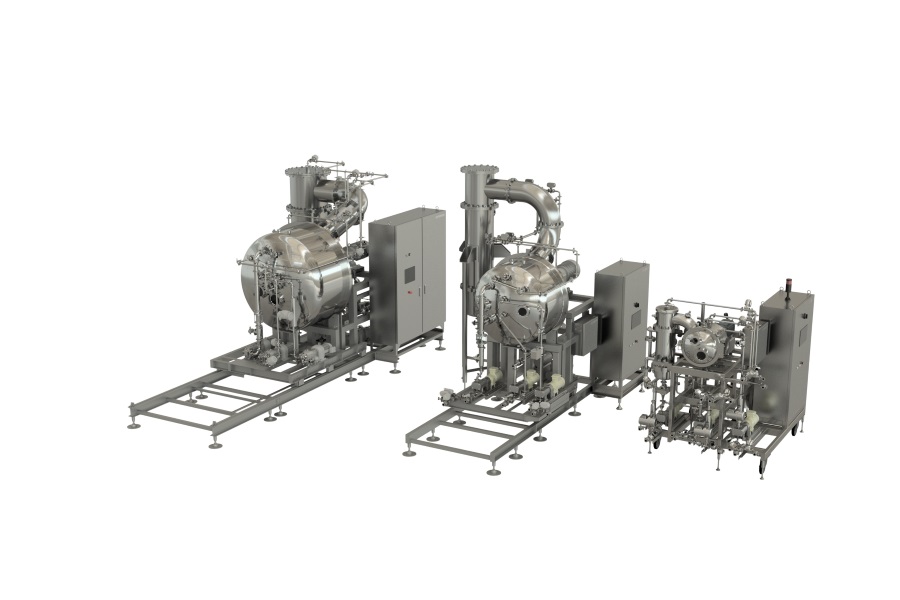

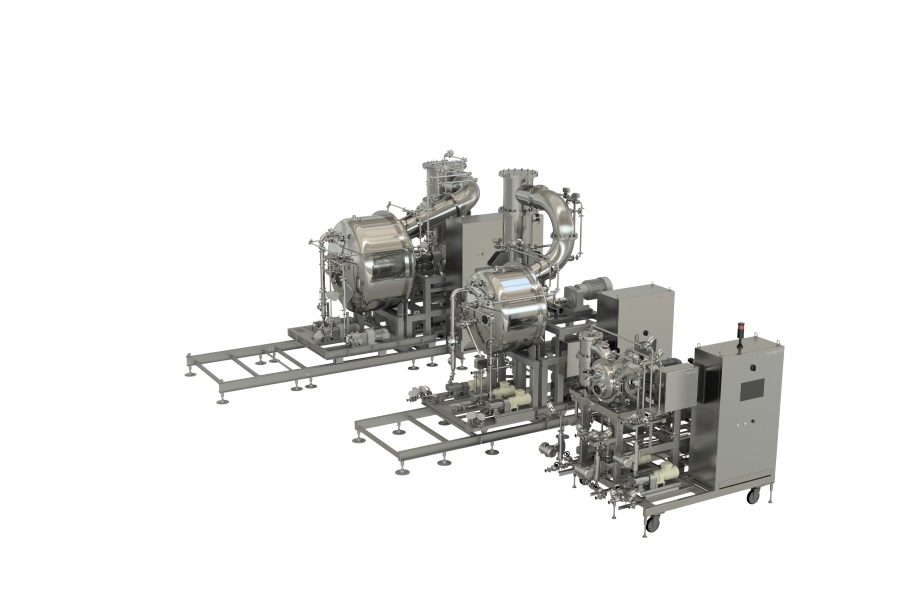

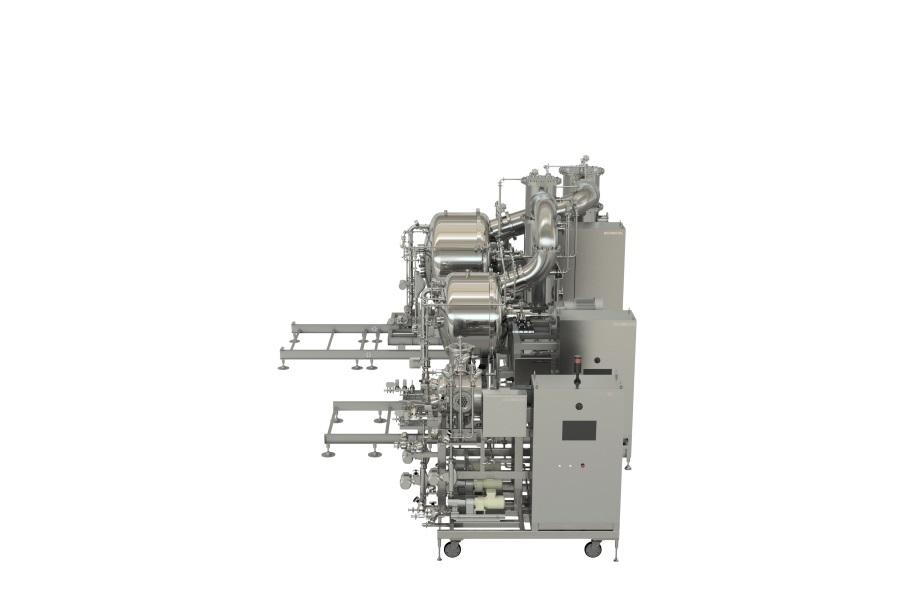

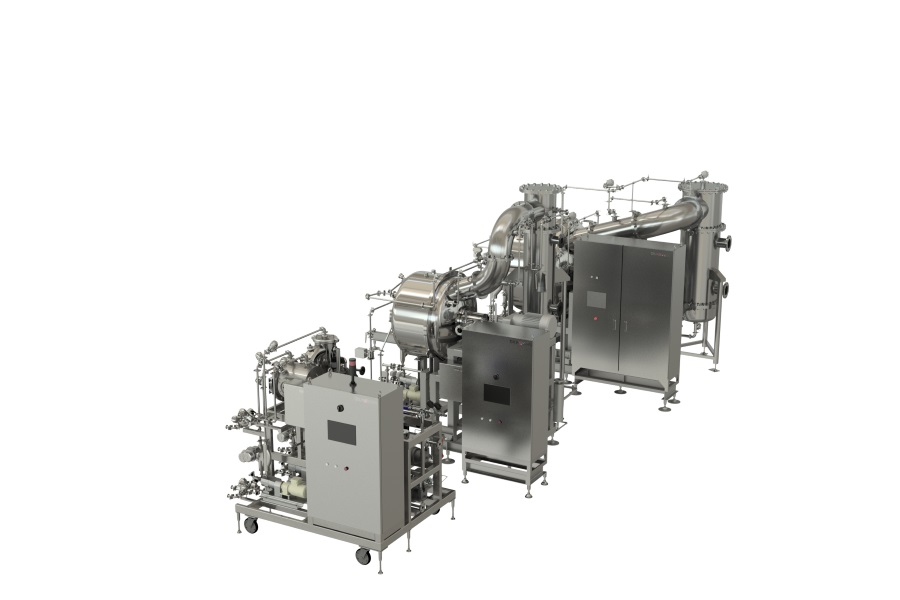

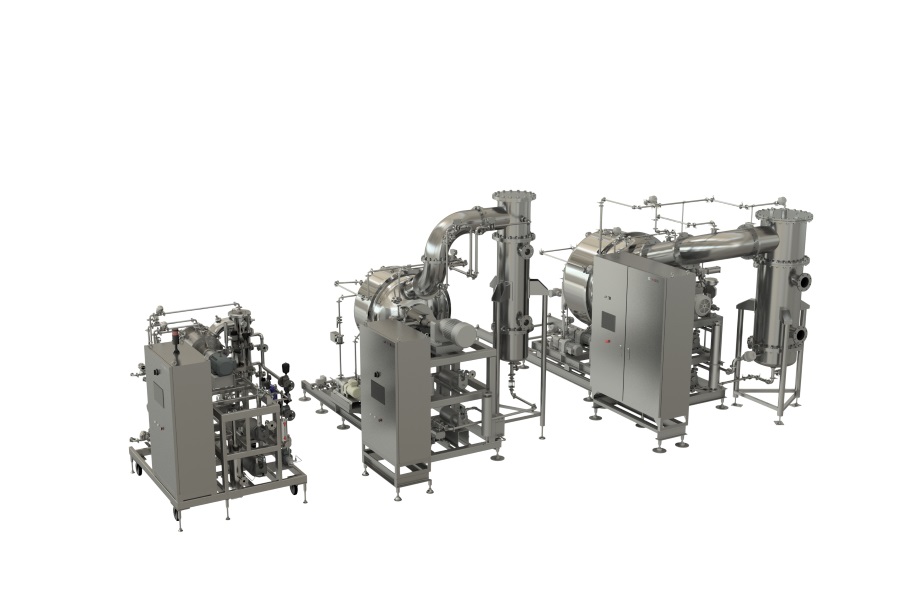

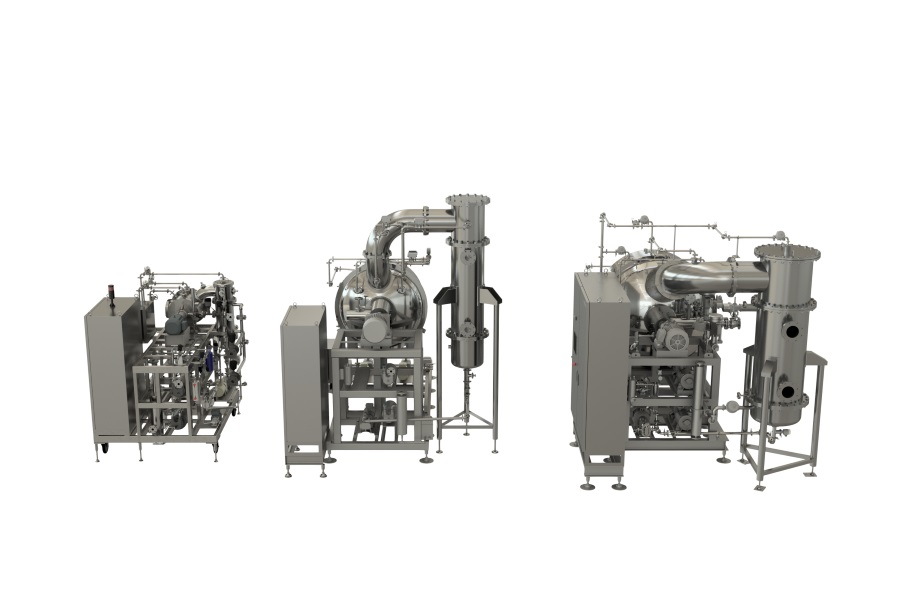

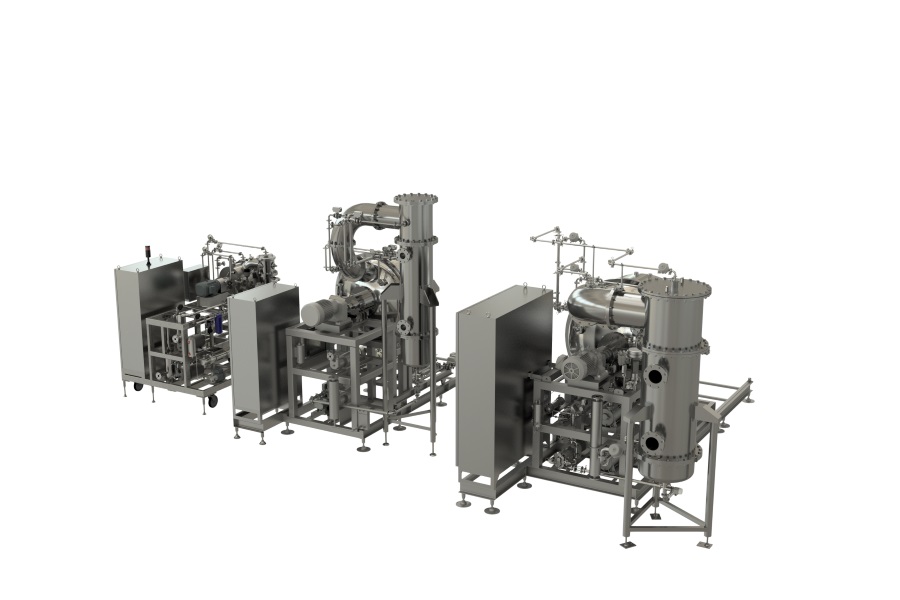

Structural Image