KPU

Classification

- Sterilization

- Food and Beverage

- Pharma and Nutraceutical

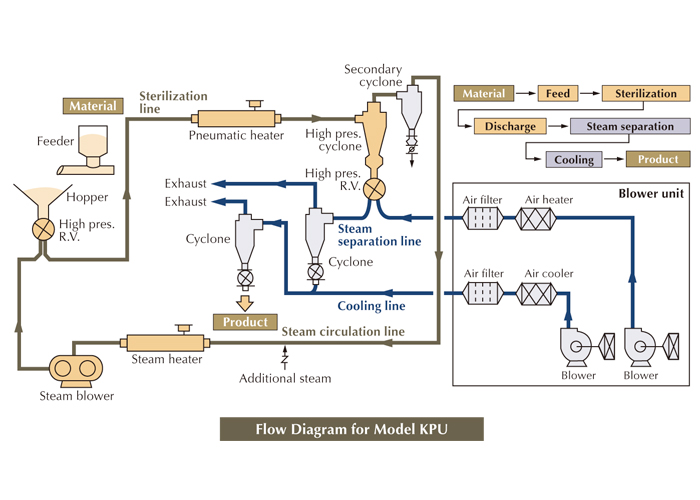

"KPU" is a system designed to use superheated steam to continuously, naturally and instantaneously (4 to 5 seconds) sterilize a wide range of powder, shredded or grain materials.

Features

- Excellent Sterilization Effect

Superheated steam provides high thermal energy, capable of disinfecting both general cells and hermoduric cells instantaneously and naturally. - Minimal Product Deterioration

Short heating time, anaerobic atmosphere and constant temperature in the airflow pipes minimize the risk of product deterioration such as loss of active ingredients or oxidation. - Wide working range and easy to use

Pressure and temperature conditions can be set as desired, allowing an extensive range of operation, and making KPU suitable for sterilization of a wide variety of powders and grain materials. - Easy Cleaning

The pipe interior can be cleaned by flushing water from the material inlet, and dried with the inline heater. - Energy-saving

Superheated steam is recycled through circulation, making it a highly energy-efficient device.

EXAMPLE OF APPLICATIONS

Spices/herbs/health foods/cereals/fish meal/tea leaves/etc.

Video

Flowsheet

Examples of Sterilization Data

| Material | Before Treatment | Conditions | After Treatment | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Viable cells (q'ty/g) | Thermoduric cells (q'ty/g) | E coli | Moist (%) | Steam pressure (MPaG) | Sterilization time (sec.) | Viable cells (q'ty/g) | Thermoduric cells (q'ty/g) | E coli | Moist (%) | |

| Black pepper (powder) | 1.6×107 | 4.8×105 | (+) | 9.0 | 0.26 | 4 | < 300 | < 300 | (-) | 4.6 |

| Red pepper(coarse ground) | 1.5×106 | 1.0×103 | (+) | 10.1 | 0.24 | 4 | < 300 | < 300 | (-) | 9.7 |

| Turmeric (powder) | 3.2×107 | 4.0×105 | (+) | 11.1 | 0.24 | 4 | < 300 | < 300 | (-) | 8.1 |

| Buckwheat (powder) | 5.1×105 | 2.0×102 | (+) | 11.9 | 0.15 | 4 | < 300 | < 300 | (-) | 9.2 |

| Dry bonito(coarse ground) | 3.2×105 | 6.9×103 | (+) | 10.6 | 0.28 | 4 | < 300 | < 300 | (-) | 9.5 |

| Psyllium husk | 1.2×104 | 5.6×102 | (+) | 11.7 | 0.15 | 4 | < 300 | < 300 | (-) | 9.5 |

| Gum Arabic (coarse ground) | 3.3×103 | 2.0×103 | (+) | 10.4 | 0.15 | 4 | < 300 | < 300 | (-) | 5.5 |

| Powder tea | 2.7×106 | < 300 | (+) | 3.4 | 0.20 | 4 | < 300 | < 300 | (-) | 3.5 |

| Green tea | 8.8×102 | < 300 | (+) | 3.1 | 0.20 | 4 | < 300 | < 300 | (-) | 4.5 |

※ Analysis method: Viable cell: By standard agar-agar plate culture Themoduric cell: By standard agar-agar plate culture (boiled for 10 minutes)

E coli: By BGLB method Moisture:By infrared moisture analyzer

※The sterilization results are examples from sterilization tests using our test equipment.

Specification

BASIC SPECIFICATIONS

| Model | Installation Spaces | Main Body Dimensions / Weight | |||

|---|---|---|---|---|---|

| Floor area (m2) | Ceiling height (m) | Width (mm) | Length (mm) | Weight (ton) | |

| KPU-10 | 50 | 4.5 | 2,000 | 1,800 | 3.5 |

| KPU-20 | 75 | 4.5 | 3,600 | 2,300 | 4.0 |

| KPU-40 | 90 | 5 | 3,800 | 2,300 | 5.5 |

※ Above figures are subject to change in detailed design.

※ Installation spaces include operation and maintenance ones.

※Pilot plant for tests is available at our technical center.

Capacities and Utilities

| Model | Capacity | Utilities | ||||

|---|---|---|---|---|---|---|

| Capacity (kg/hr) | Max. pressure (MPaG) | Sterilization time (sec.) | Steam (kg/hr) | Cooling water (L/min) | Power (kW) | |

| KPU-10 | 100 | 0.3 | 4 | 80 | 25 | 60 |

| KPU-20 | 150 | 0.3 | 4 | 100 | 30 | 75 |

| KPU-40 | 350 | 0.3 | 4 | 180 | 35 | 120 |

※Capacities are based on powders with a bulk density of 0.5kg/L and may change depending on material properties.may change depending on material properties

※Steam consumption depends on the material being processed as well as operation conditions.

※Steam consumption value is for stable operation. In equipment startup and cleaning, approx. 5X of steam may be required.

※Cleaning water is needed (equipment cleaning process).