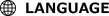

SUPER ROTARY DRYER

Classification

- Drying

- Food and Beverage

- Organic Chemicals

- Inorganic Chemicals

- Feed & Fertilizer

The Super Rotary Dryer features a disintegrator in the rotating drum to effectively make the material contact with the hot air. Not only the sludge from waste water treatment system but dewatered cake, muddy and solid materials can be dried into granular product continuously and uniformly in a short time.

Features

- High performance in a small unit

- Energy-saving

- Wide application

- Flexible to evaporation rate fluctuation

- Easy operation and maintenance

- Quality product

Typical Applications

- Inorganic substances

Calcium carbonate, calcium molybdate, lead-refining material, lime stone, iron ore, steelmaking byproduct, precipitated copper, iron oxide, ferrite, manganese oxide, manganese dioxide, manganese sulfate, copper sulfate, silica sand, glass powder, talc, granulated lime, kaolin, sodium siliceous fluoride, sodium fluoride, ortho sodium silicate, potassium titanium, potassium phosphate, active white clay, iron hydroxide, copper hydroxide, aluminum hydroxide, silicon carbide, anhydrous sodium sulfate, aggregate, soil and stone, refractory material, lime, insulation material, culture media - Food products, etc.

Instant bouillon, bread crumbs, orange skin, animal feed, fertilizer, pet foods, starch waste, soybean curd waste

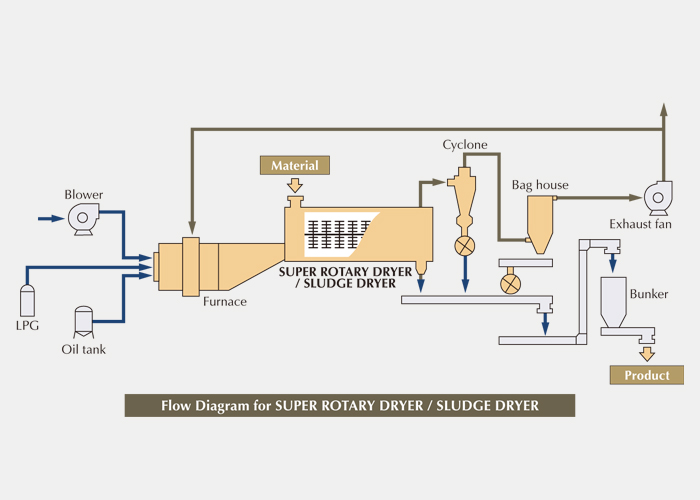

Flowsheet